|

|

|

| INTERNATIONAL PROGRAM | INDUSTRIALLY DEVELOPED COUNTRIES | |

|

|

| |

INDUSTRIAL SYSTEMS DESIGN &

INTERNATIONAL

PRODUCTS DEVELOPMENT

The

series of articles program

consists of modern industrial systems automated

or semi-automated development

and adapted to the quick change of products

inside the same production line, including FMS– Flexible

Manufacturing Systems, or industrial cell

systems and Rapid Products Development, rapid prototyping

and

rapid tooling.

Inside these concepts new several raw materials, processes,

design and technologies are proposed in our international

partnerships with researchers, Institutions and

development centers, engineering and industrial design

companies , industrial systems

design and raw materials manufacturers.

A great range of products

is accessible in partnerships and available for immediate

production, may possibly

include molds tools and complete systems

ready for

production.

Information links are provided

about all proposed themes.

|

__ INDUSTRY MAIN TRENDS __

Establishing

main parameters for the current

industrial development, it can

be defined two main

axes as trends from the last

years:

¤ FMS – Flexbile

Manufacturing Systems

¤ Industrial Systems without own industrial facilities

Other tendencies

can be mentioned, but that are composed mainly

inside trends of ramifications as Petroleum,

Chemistry, Mechanics of Precision.

|

|

| |

FMS - FLEXIBLE MANUFACTURING SYSTEMS

Basically

a FMS is defined as an integrated and automated production

system containing:

(a) flexible

process equipment, normally automated machines with numeric

control and equipped with

quick tool change ability,

(b)

material handling equipment including transfer

lines or conveyor belts, forklifts, elevators,

automated guided vehicles (AGVS) as well as

automated storage and inventory handling systems

such as automated storage and retrieval

systems (ASRS),

(c) sophisticated computerized communication and control systems integrating

process and material handling equipment, and

(d) a modern maintenance support structure that can bring the system

quickly back to normal after equipment failure.

FMS is designed mainly for the existence

of multiple production lines inside the same facility,

or even for the fast change of production lines. FMS for

its properties adapts mainly for the industrial suppliers

working for third-parties, and they are especially

endowed with versatile systems capable to comprehend

an extensive production range inside a domain, as assembling,

plastics production, chemical, agro-industry, machining

and mechanical assembling, involving even finishing

and

packaging.

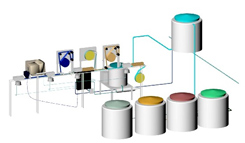

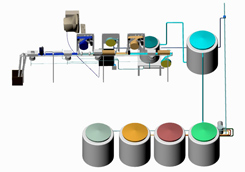

The images represent the schematic FMS Hydrogel plant in

a project funded by International Atomic Energy Agency

(IAEA) and IPEN Nuclear Energy Research Institute.

Fig.1 (top) represents the basic process with magazine

for molds tools swap on the blistering machine, with

automated conversion of ingredients addition.

Fig. 2 (center) represents the FMS plant including a

system where packaging recipients inside the mold cavities

(interchangeable magazine) serves as mold shape for Hydrogel.

The packaging systems is integrated to the process.

Fig. 3 is a schematic

FMS plant including packaging systems and irradiation

unity.

See FMS - Flexible

Manufacturing Systems Design article See FMS - Flexible

Manufacturing Systems Design article

|

|

|

|

_________________________________________________

INDUSTRIAL

SYSTEMS

Without own industrial facilities

Industrial

corporations without own industrial facilities have

been effectively the most important trend of the

last fifteen years, beginning with the large

multinational corporation and reaching nowadays every

levels of correlated

industry mainly within the international

market.

The evolution of the subcontracting systems all over

the world and the vertiginous increasing of the efficiency

progress of the services and production suppliers, quality

and time optimization, transformed the industrial perspective.

Pressing

the traditional models with the new economical models,

and causing a spectacular reduction in the periods,

the system of industrial subcontracting reached unexpected

domains.

The reduction of the industrial corporate administration

team, also forces to an optimization of the functions

and amplification of the skills and responsibilities.

The decision-making is more reliable, but it holds

more centralized consequences and responsibilities.

|

____________________________________________

STAFF & SKILLS

New

Industrial Model

The nature and character of the

current international environment which staff works in

new industrial corporation is now more complex than ever,

and the skills that are needed extend beyond Information

and Communication Technologies to embrace the analytical

and evaluative skills essential to effective information

management. In

the new staff roles is important to define and map

staff development needs and thrust in terms

of their

information skills, creating a model for staff

to use in developing their information resources.Continue

collaboration with key staff development and information

agencies/organization, including

the development

of a ‘roadmap’ to their various roles

and initiatives, providing guidelines and advice

for the

company on developing their staff’ information

skills and the expected benefits for the organization

and the productive system development.Some

of these information's are available at Internet

as marketing reports and analysis for

each domain

and locality, since US$50. Workings in an electronic

environment

increases dependency on information; identify,

assess, retrieve, evaluate,

adapt, organize and communicate information

within an recurring context of evaluation and deliberation.It

is of highest importance that all staff employed

in the industrial corporation sector is

given support

to develop confidence and competence in

their ability to identify and apply quality information,

to inform

and add value to their working proceedings.It

is evident that staff needs more than just

particular skills to feel confident

working with the wide range

of information sources available today;

consider the cumulative impact of recent industrial

tasks

development, the incremental shift from

informative to structuring

productive chains.

The

most important benefits from a motivated staff are

improving information flow,

use of existing resources,

return on investment, research capability,

and enhance market profile and reputation.

|

_____________________________________

INDUSTRIAL

SYSTEMS

Subcontracting Model

The schematic model distributes

the basic components of the industrial structure of subcontracting,

considering as successfully efficient a basic structure

from a staff

of three qualified managers to ten/twelve

for the administration of 20/25 products in the international

market. Starting from the establishment of a reliable Intranet/Internet

portal, the actions of the team lead using this tool

to interact among information agencies/institutions (marketing,

consultants, analysts), services (Design, engineering,

prototyping, molds and tools), producers (industrial

suppliers) and distribution. Effectively the development

stage doesn't settle down on a sequential way, but intercalated,

compelling to multiple

tasks during the development period. The model establishes above all horizontal structures

than vertical, or meaning all the team members shall

interact in the decisive process; in reality the model

demonstrates in the outline, it even imposes the interaction

among the several suppliers (services, goods and consultants). The principal net benefits of this structure it is the

elimination of the periodic flotation (seasonality),

maintaining an increasing evolution of the profitability,

and suspending acquisitions when the market is reduced

without implicating in maintaining a structure of workforce,

facilities, machines and equipments. Other benefits may

be Improved use of existing resources, return on investment,

and research capability.

The

complete presentation of tasks, functional organization

and optimization

may be seen in RPD–Rapid Product

Development.

|

Integrated International Subcontracting Scheme

Advanced

IT – Information Technology Systems have to be

provided for a reliable International industrial company

without

own industrial facilities. An optimized team enclosing

the four main responsibilities supports the organization:

Company header, Product Management, Financial Management,

and Marketing Management.

Within each division in the Intranet/Internet WEB Portal

the KM – Knowledge

Management system, arrange and dispose to all team the main information related

to each initiative, state, situation, and involved decisions or tasks.

The external services, suppliers and consultant interact with the manager's team

by means of Internet/Intranet WEB portal and other communications interfaces

(fax, telephone, etc).

Every data from budgets, invoices, data, costs, orders, are integrated to Intranet

Portal in real time, and by means of administration interfaces, integrating all

available data, files, pictures, and documents.

The integrated system updates directly all data from statistics, cash flow, storage

flow, orders, requests, and information.

The databases are integrated to the Knowledge Management system supplying updated

information on real-time.

|

|

|

|

|

|

|

|

|