|

|

|

INDUSTRIAL PROGRAM | ISOTAT

I|

|

|

|

| |

ISOTAT

INTEGRATED SYSTEMS OPERATION TECHNOLOGIES & ADVANCED TRAINING

INTELLIGENT OPERATION SUPERVISORY SYSTEM

_ ISOTAT WEB PORTAL MODEL - MAIN

SECTIONS CONTENTS _

PROCEDURES GUIDE |

SYSTEMS STATE -

SIGNALS PROCESSING |

GUIDES-DIRECTORIES

|

Main utilitarian containing the principal systems or

subsystems informative, shutdown and startup, recommendations

and interconnected to the training systems and decision-support. |

Utilitarian

interconnecting all the systems of available information,

in real time,

and appropriating actions

and decision-support to the real operational

conditions, including states of alert, maintenance

breakdowns

foreseen and in course. |

Guides

and directories interconnect operators and users

to every schemes of guides and information system.

It allows the location of information and resources

obtaining

for decision-support or attitudes according to

the established patterns, to find sections responsible,

instructions

or support. |

DECISION-SUPPORT |

e-Monitoring |

e-Maintenance |

Systems based on norms and operational directing patterns

of the company, comprising instruction elements and resources

for decision-making, including training in existent interconnections

in the own resource. The systems are updated in real

time and they can be directly connected to the video

monitoring for evaluation of situations dependent of

physical supervision or instruction to operators and

services of local maintenance. |

Basic information system of every systems and subsystems

components allowing the interoperation with the operating

systems, auto-identification, operation, control, command,

e-Maintenance, and commanded video supervision, integrating

all the signals and available processing in the systems

and simulators. |

Integrated

into e-Monitoring systems, the e-Maintenance

systems incorporate

the procedures of preventive Maintenance,

Corrective Maintenance, predictive Maintenance

and degradation of systems indicators through

a system’s

lifecycle. |

VIDEO SUPERVISION |

INDUSTRIAL PLANT OPERATOR TRAINING |

SAFETY |

Video systems manipulated, could incorporate filters

for alert of state or intrusion, infrared temperature

control, laser, allow the routine local inspection to

the distance, control and maintenance support and remote

operation. |

Operators Training System containing training in the

job desktop, integrated into the current project control

of operations content and incorporation the most recent

concepts of Industrial plants operation. |

Integrated Safety System, interpolating safety instructions

with systems state and alerts, directories of safety

and emergencies resources and procedures guide. |

PLANT MANAGEMENT |

SECTOR ADMINISTRATION |

COMPANY INFORMATION |

Integration of the means and resources of general administration

of Industrial Plant, incorporating state of systems and

subsystems, production controls, maintenance forecast

and maintenance in course, control and operation of the

supervision video systems, operational, functional administrative

interfaces, control of stocks of spare parts, materials,

personal. |

Sectorial

administration Integration

of methods and resources,

incorporating systems and subsystems

state, operation controls, maintenance schedule

and maintenance in course, control and operation

of video

monitoring

systems, sectorial administrative interfaces,

functional, spare parts stocks control, materials,

staff. |

Integrated Company system

with corporate information, norms and procedures, statistics,

staff sectors and human

resources, interlinked to Company generic systems. |

OPERATING |

MAINTENANCE |

DOWNLOAD |

Plant

operating at technical and operational management

level. These tools use complex contents and they

can make appeal to open modeling processes, fed

and updated

by the administration interfaces. |

Information

Systems Maintenance, solution-aid of problems for technicians.

These tools will make use of simulation

of arguments associated with equipments models and/or

of the complex processes. |

System

of files available for individual download of courses,

trainings, instructions, statistical, utilitarian

and software, plug-ins, animations, videos, simulations.

These systems deliver to the autonomous posts

matters

of daily or special use, avoiding overloading

the Internet Broadband systems while the occurrence

of urgency events. These downloads

can be autonomous, compulsory and automatic for

indicated job posts.

|

___ WEB OPERATIONAL PORTAL DESIGN ___

Design, tracing specifications, dimensioning

purposes for management of the industrial

productive systems.

These tools are necessarily interactive and they

can make appeal to reasoning modelers introduced

by training

systems and online decision-support.

|

_PROCEDURES EDITOR _

INTERACTIVE

PROCEDURES GUIDE projected leaning on Editor

of Procedures Intelligent, through WEB

administration interfaces, capturing, structuring

and storing knowledge, and offering an integrated

information tool, understanding training and procedures

application and situations through training, simulation

and decision-support.

Incorporation

of interactive and intuitive procedures editor

so that the guide can be modified and updated easily

(portal WEB), for every involved hierarchy, without

demand of special computer knowledge and integrating

every types of files, animations, images and formats.

_ EDITOR

OF PROCEDURES _

SYSTEMS DIAGNOSES

Observation:

This system is interconnected and dependent of

e-Monitoring and e-Maintenance applications, existent

and/or in installation inside of a current project,

and conditioned by the level of available information

and data of the system current, and according to

their adoption by the company, recommended by the

current project:

¤ Disposition

and structuring of available observations to identify

a defective component or malfunctioning, systems

degradation, number and difficulties of interpretation. ¤ The

decision-support system drawn for a complex system;

should interpret initial observations and transform

them to a succession of complex tests, in reason

of the system diagnosing difficulty, according

to the patterns and norms of the Company (contractor))

and his suppliers. |

¤ Development

of structures of tests and verifications of multiple

components and subsystems that interact to each

other in complex manners.

¤ Development

of structure of tests (with the contractor company

management team) that lead to a more efficient

way to discover the defective component or components,

as well as assure a highly precise diagnosis.

¤ Development

of editor of wrong diagnosis consequences and frequency.

Reasons for diagnosis mistake are numerous. Induction

of reasoning process that can be formalized or

built-in in a specialist system of help in the

process of problem solution, during the execution

(development with the contractor company management

team).

¤ To

develop correctly the requested tests and procedures

actions and training.

¤ The

advanced training can be implemented efficiently

(optionally) using a software tool simulating and

providing orientation of the process of solution

of problems efficiently. The expectations of such

tool are that it guides from the beginning, step

by step the user, for the solution process of present

problems and transfers from the reasoning process,

evaluating whether the procedures are correctly

applied. As a second phase, it can be important

to evaluate the base of acquisition of the reasoning

logic. |

GUIDE

OF

TROUBLESHOOTING SOLUTION

Decision-support

based on Company procedures and norms, available in

the WEB operation interfaces, with distinction of levels

and accesses, and updated in real time according to

the updating or equipments and procedures modification:

¤ Guides

of troubleshooting based on three phases that

characterize this training, will be integrated into

the simulators:

¤ The

discovery phase where the user identifies each

element that composes a circuit, fail potential operations

and the repair methodology and/or associated

maintenance.

¤ A

phase of analysis of fail operation " guided " while

the user will be capable to confront with the

maintenance or adjustment and where each step

will be taught

by the tool.

¤ A

final apprenticeship phase of analysis of fail

real operation, where the user is forced to dominate

individually

and where each action is registered. Analysis

of the method used by the user creates a computation

that takes into account the time and cost of

the

different parts activated during the operation.

|

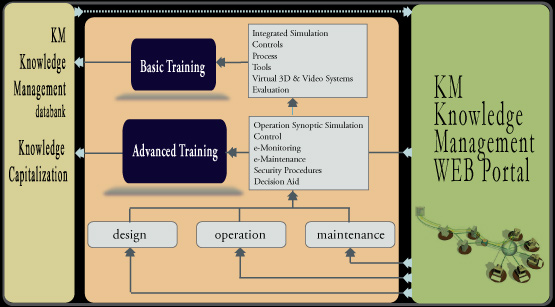

KM - KNOWLEDGE MANAGEMENT

Methodology

development of systematic incorporation

of the processes evolution, applied in the interpolation

of the Knowledge Capitalization to the KM base model.

Standardization of the technical culture, while offering

information and provide aid on-line, at any hour

and anywhere, when demanded. In the advanced training

three dissemination types will be distinguished:

a)

The applications of KM - Knowledge Management will

be defined for the operational process, and limited

to

the relative specifications for the Industrial platform

systems operation destined to:

i)

Preserve the company knowledge related to the systems

operation (current phase) of Industrial platform,

training and formation, safety and operational

norms.

ii)

Establish the knowledge bases implicated in the

operation of systems and their interrelationship.

iii)

Development of an open KM base (current phase), destined

to the future integration

of the other

systems of the company.

|

iv)

Simultaneous incorporation of the whole base of existent

knowledge, related to

the systems operation,

their organization

and use of different applications according

to the convenient approach.

v)

Incorporation of the constituent elements of the

corporate training, which is

not function dependent, and which

enclose the employees' totality – Safety,

norms, etc..

vi)

Design of the database structure to incorporate systems

already in use

in the

company.

vii)

Elaboration of administration interfaces of the KM

systems.

b) Applications of KM - Knowledge Management in

training systems, contributing to the standardization

of the technical

culture, while offering information provide aid

on-line when requested, at anytime and anywhere.

c)

Use of technologies of instructive design and instructional

technologies, for obtaining

important

reduction in training

time and quality:

i)

Effective incorporation of simulation tools

into the training modules, being considered one

simulation basically

for each training module

|

ii) Integration of videos, films and animations,

existent in the collection of material

accomplished previously

by the contractor Company, in the effective

integration of trainees to real situations, and incorporating

cognitive

qualities. Use of video under demand

technologies.

d) Simultaneous decision-support tools development in

parallel to the training systems:

i)

The systems of decision-support will integrate operational

norms and procedures updated practically in real

time, consulted by WEB operational portal interfaces

and updated

by the administration interfaces.

ii)

The elements of priorities and decisive factors in

the operation

of complex systems incorporate the principal

elements of data, information and knowledge of

systems operation, constant of the equipments norms

and operation

know-how, safety and active recommendations of

the concerning sectors. |

|

|

LabGraph

digital Laboratory

ISOTAT - Training Systems for Petrochemical, Chemical or Pharmaceutical and process facilities using Virtual Reality, Simulation, KM and online decision-support.

International partnership with top Training & Research institutions for designing Integrated Intelligent Operation Online Training Systems for on post and within work time training.

LabGraph LabGraph

|

| |

| |

| |

| |

|

|

|

|

|

|

|

_ ICMA SYSTEMS SCHEME ___

The

development of the architecture of systems

designated ICMA -

Intelligent Control Monitoring Architecture, of

monitoring industrial production by networks, is

destined to allow control specialists to monitor systems (e-Monitoring)

remotely by modem

connections of high security.

The international consortium will establish the

parameters jointly with the contractor company engineering

for the establishment of the

first

phase of systems services including:

• Remote

diagnosis

• Management

of systems

• Answer event-actuated

• Spare parts

stock optimization, remote spare parts and services

support

• Systems

specialists' support.

Developing

techniques of predictive service, provide a cost-effective

way to maximize the availability

of the system in the current configuration.

|

ICMA

INSTALLATION & SERVICES

¤ Signal Processing: Evaluation of existent systems

that

use neural networks, and linear or non-linear classic

control approaches and combinations of these.

¤

Evaluating of the reliability

of existent complex systems using sensors data

analysis. Based on sensor

data, it can

be obtained a very high success rate; discovering

and diagnosing problems precisely

before

originate system degradation or catastrophic breakdowns.

¤

Tailor model development

for the systems, subsystems and equipments,

configuring the existent

current

system for the interfaces and simulations, and

establishing

the ideal

parameters for the evolution of the systems.

|

|

SIGNAL PROCESSING

SCANNING OPTIMIZATION

Applying

both digital conventional and the

modern tools of signal processing

for analysis of main components in

a large amount of applications as 3D image processing,

computer

simulation, system

recognition, adaptive series, data

and

video compression, monitoring reliability establishes:

¤ Simulation improvement

¤ Scanning system improvement

¤ Multifunction processing of sequences series

¤ Data, and video compression

¤ Task recognition or automatic objective

¤ Prediction of traffic of communications networks

¤ 3-D image analysis and exhibition of sensor

data

_VIDEO REMOTE MONITORING_

Hardware & software

systems installation of remote Video Monitoring

allowing video cameras industrial

monitoring to have positioning and interactive zoom,

with images fixed and/or sequences recorded memory.

|

To

establish base patterns for filters comparing:

¤

Predefined sight of gates

¤ Equipment measures, levers position, etc.

¤ Movements detection

¤ Smokes, leaks

¤ Reduction of inspection costs and responsibility

costs for accidents or incidents. Periodic

visual specific check-in, and daily or hourly check-in

of each component

per time.

¤ Systems Installation able to compare patterns

graphically for precision control and

production quality.

The

system will be configured to have intrusion alert

and support for maintenance services.

Installation of Hardware of industrial Automation,

software, and application services networks-based

Installation of remote Video Integrated with

Technologies of Communications Video IP node.

Monitoring Characteristics Utilities Benefits:

- Camera

video interactive 360 degrees - remote panoramic

control and zoom

- Reduction

of environmental responsibility

- Reduction

of intrusion responsibility

- Reduction

of inspection expenses

- Reduction

of trips costs

- Increase

of inspection frequency

- Reduction

of failure of power time

- Equipments

damage reduction

|

|

|

|

|

|

|

|

|